CNC Turning Lathe Machining Large Diameter Dn200 Flow Conditioner From 304 Stainless Steel

Basic Info

Model No.: customized

Product Description

Model NO.: customized Standard: GB, EN, API650, China GB Code, JIS Code, TEMA, ASME Production Type: Batch Production Material: Aluminum, Stainless Steel 304 Tolerance: +/-0.01 Trademark: RuiXing Specification: customized Application: Machinery Accessory, Instrument Accessories Surface Treatment: Natural Machining Method: CNC Machining Size: According to Custom′s Requirement Be Used in: Flow Meter Part Transport Package: Bubble Bag and Cartons in Pallet Origin: Shenzhen, Guangdong (1). Material: stainless steel 304

(2). Surface Finished: Natural

(3). Process: CNC milling, CNC machining

(4). Tolerance: 0.02mm

Parts Information:

(1). Applicable Material---Aluminum (6061,6063,6082,2011,2017,7075) ,zinc alloy, iron, steel alloy(4140,4340,Y40Mn,40Cr,1018,1080), plastic(POM,Derlin,PC,PMMA,Nylon, PP,Teflom,PEI,Ultem,PEEK), brass, steel(12L14,1215), and stainless steel(303,304,304L,316,316L).

(2). Surface treatment--- anodizing, plating, polishing, painting or as your request.

(3). Payment Terms: 40% deposit before production and 60% balance before shipping

(4). Packaging: Standard package/ Pallet or container/ as per customized specifications.

(5). Shipment Terms: Express & air freight is preferred / sea freight/ as per customized specifications.

Our office

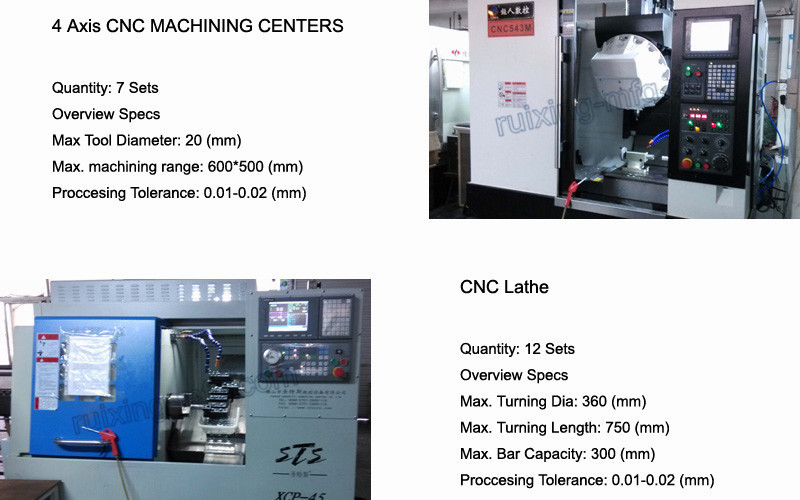

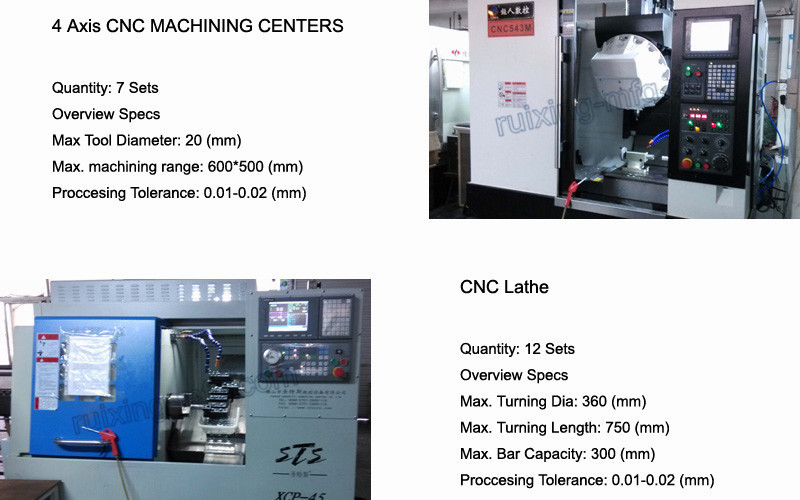

Our workshop

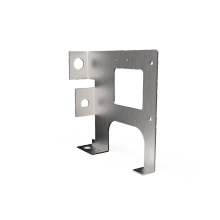

Our products

Our Advantages:

1. We have over 12 years' experiences on CNC machining and have produced a wide variety of industrial products which being sold to the United States, Canada, Germany, Japan and the Netherlands etc.

2.We have very stable engineering team, some of them have about 20 years' experiences.

3. We can use different softwares including Proe, UG, Solidworks, Mastercam and CAD etc.

4. We provide both OEM and ODM services to our customer.

5.Tight schedule prototype manufacturing, normally the timeline will be controlled within one week.

6. Our minimal order can be 1 to 5 pieces according to customer's convenience.

7. We have very strict quality control system, all parts are under 100 percent inspection before shipping.

8. Flexibility of management and production to guarantee the delivery time.

9. We are a manufacturing factory with different equipments in house(turning, milling machine etc), so we can provide the best competitive price to our customer.

10. We insist on quality first and customer foremost, so we always provide best services to our customers such as design analysis, rapid Prototyping, following schedule strictly and reasonable price etc.

Welcome to RuiXing Precision Manufacturing Co.,LTD

http://www.ruixing-mfg.com http://szruixing.en.made-in-china.com http://szruixing.en.alibaba.com Contact us if you need more details on Machining Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Flow Conditioner、Large Diameter Turning. If these products fail to match your need, please contact us and we would like to provide relevant information.

(2). Surface Finished: Natural

(3). Process: CNC milling, CNC machining

(4). Tolerance: 0.02mm

Parts Information:

(1). Applicable Material---Aluminum (6061,6063,6082,2011,2017,7075) ,zinc alloy, iron, steel alloy(4140,4340,Y40Mn,40Cr,1018,1080), plastic(POM,Derlin,PC,PMMA,Nylon, PP,Teflom,PEI,Ultem,PEEK), brass, steel(12L14,1215), and stainless steel(303,304,304L,316,316L).

(2). Surface treatment--- anodizing, plating, polishing, painting or as your request.

(3). Payment Terms: 40% deposit before production and 60% balance before shipping

(4). Packaging: Standard package/ Pallet or container/ as per customized specifications.

(5). Shipment Terms: Express & air freight is preferred / sea freight/ as per customized specifications.

Our office

Our workshop

Our products

Our Advantages:

1. We have over 12 years' experiences on CNC machining and have produced a wide variety of industrial products which being sold to the United States, Canada, Germany, Japan and the Netherlands etc.

2.We have very stable engineering team, some of them have about 20 years' experiences.

3. We can use different softwares including Proe, UG, Solidworks, Mastercam and CAD etc.

4. We provide both OEM and ODM services to our customer.

5.Tight schedule prototype manufacturing, normally the timeline will be controlled within one week.

6. Our minimal order can be 1 to 5 pieces according to customer's convenience.

7. We have very strict quality control system, all parts are under 100 percent inspection before shipping.

8. Flexibility of management and production to guarantee the delivery time.

9. We are a manufacturing factory with different equipments in house(turning, milling machine etc), so we can provide the best competitive price to our customer.

10. We insist on quality first and customer foremost, so we always provide best services to our customers such as design analysis, rapid Prototyping, following schedule strictly and reasonable price etc.

Welcome to RuiXing Precision Manufacturing Co.,LTD

http://www.ruixing-mfg.com http://szruixing.en.made-in-china.com http://szruixing.en.alibaba.com Contact us if you need more details on Machining Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Flow Conditioner、Large Diameter Turning. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Stainless Steel Machining Parts

Premium Related Products

Other Products

Hot Products

Custom Made Spare Part of Bicycle ComponentsCNC Machining of Brass Hardware PartsCNC Machined Part of Equipment Accessories (Stainless Steel Non-Standard Part)Customized Sand Casting for High Manganese Steel Connector in ChinaOEM Lost Wax Casting for Concrete Mixing TruckAluminum CNC Machining for E-Cig Kit AccessoriesOEM Spare Parts for Agricultural Machinery Investment CastingSpare Parts of Atomizer Used on E-CigOEM High Manganese Investment Steel CastingOEM Investment Steel Casting for TrainChina Cheapest Carbon Steel Foudry for Auto PartsCNC Machining Part for Faucet or TapCNC Machining Part for Various Industrial UseCNC Machining for Equipment Accessories (Steel Part)Aluminum CNC Sewing Machine Spare Parts with Anodizing TreatmentCNC Machined Part of Equipment Accessories (Steel Non-Standard part)